Facility in Focus Series:

An Inside Look at Northwest Pipe’s Manufacturing Plants

With 13 facilities in the U.S. and Mexico, Northwest Pipe Company (NWP) plants are strategically located to support water infrastructure projects in communities across North America. Each facility offers a range of manufacturing capabilities and specialized services that provide engineered solutions for water transmission, wastewater, stormwater, and process system applications. Although geography and product specialty vary from plant to plant, our commitment to quality, service, and safety remains unwavering across locations. In our Facility in Focus series, we take a closer look at each of our plants, showcasing the unique manufacturing capabilities, technology, and skilled workforce that power the production of our innovative and durable water infrastructure products.

The Houston Plant

ParkUSA – A Northwest Pipe Company | Engineered Water Technologies

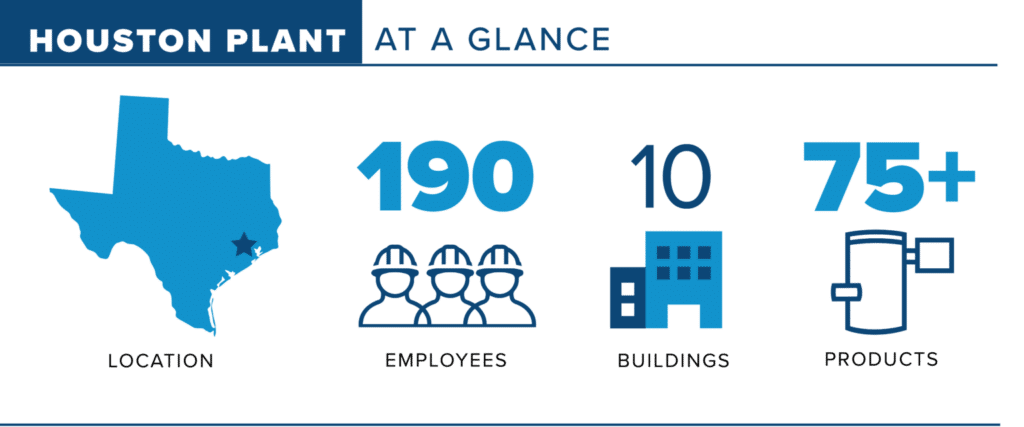

NWP’s Houston plant is the operational hub of ParkUSA, A Northwest Pipe Company, which also includes locations in Ferris and San Antonio, Texas. Built on 30 acres northwest of the downtown core, the Houston campus comprises three office buildings housing the ParkUSA administrative offices and seven industrial production and warehouse buildings. Our facilities are equipped for full-scale production of an extensive line of pre-engineered and pre-assembled water technologies and precast infrastructure components, with departments specializing in metal fabrication, concrete production, plastic production, assembly, paint and coatings, and transportation logistics. The Houston plant also operates a fleet of trucks with trailers and cranes that offer local delivery and installation support. Over 190 talented individuals make up the Houston team.

ParkUSA was founded in 1984, steadily growing its operations, industry expertise, and product catalog over several decades before being acquired by NWP in 2021. Today, ParkUSA is a driving force of the Company’s engineered precast infrastructure division, offering clients innovative and easy-to-install solutions for water distribution, wastewater pre-treatment, stormwater, and process applications.

From Concept to Customer

The Houston plant’s administrative offices serve as an incubator for design and new product development. The plant once served as a headquarters and still houses much of the sales and service activities. The Product Development team works to conceptualize new products based on our customer’s evolving needs and the increasing demand for sustainable water quality solutions. ParkUSA holds multiple patents for cutting-edge technologies, like, for example, the Coalescing Media Pack—an enhanced gravity oil-water filtration system utilized in several of our stormwater and wastewater pre-treatment products.

Down the hall, our Engineering department collaborates with clients and our production team on project designs, ensuring specified products meet exacting site requirements while complying with municipal codes and environmental regulations.

Many ParkUSA Sales and Customer Service team members are headquartered here and supported by the local Marketing team. Also playing a key role in supporting overall operations at ParkUSA are the IT, Human Resources, Purchasing, and Accounting teams. Park Process, our brand specializing in industrial process water equipment, also functions out of the Houston office.

Manufacturing Excellence

The Houston plant’s manufacturing operations can be categorized into four main areas: steel fabrication, concrete production, plastic production/paint and coatings, and assembly and controls. Each of these departments is helmed by a dedicated team that lends their specialized skills to an essential part of the production process.

Concrete Production

The concrete production team has over 70 employees and manufactures precast infrastructure components and vaults in a variety of shapes and sizes that are used to house the interior working components of ParkUSA products. Some of our most popular precast products include pump lift stations, stormwater separators, and grease interceptors. We utilize self-consolidating concrete in a wet cast process which results in a smooth surface finish and is also ideal for liner anchor embedment. Our precast products are reinforced with steel rebar for added strength and durability. The Houston plant is an NPCA-certified facility, meaning our concrete production team upholds the highest standards in the industry.

Steel Fabrication

The steel fabrication department consists of nearly 40 team members, many of whom are certified welders tasked with fabricating intricate steel product encasements ranging from standard sizes to multi-story custom units. Products commonly specified in steel include break tanks, grease interceptors, grit-oil separators, and elevator sump systems.

Plastic Production/Paint and Coatings

Depending on the application, ParkUSA products can be enhanced with a variety of coatings and linings that offer additional protection from corrosive wastewater gases or the elements. The Houston plant’s paint and coatings department includes 15 team members who weld protective plastic liners and hand-spray epoxy, polyurethane, or other specified coatings that can extend the service life of our products in even the harshest environments.

Assembly and Controls

The next step in the manufacturing process is pre-assembling the system components, including all interior valves, piping, filtration media, and sensors. These specialized tasks are executed by our eight-person assembly team. Many Park products come available with automated remote control panels, which are programmed and assembled at the Houston plant by our controls automation technicians and delivered to the jobsite ready for connection.

Before any product leaves the plant, it is inspected by our quality control technicians to ensure it meets our standards of excellence, all project specifications, and our customers’ expectations for performance.

Delivering on Service

The Houston plant’s site distribution and warehouse teams keep materials and products moving efficiently throughout the facility. Their coordination ensures stock levels are balanced and that works in progress are always in the right place for the next step in production. When a project is ready for shipment, the team carefully loads each product onto the truck, with all components pre-assembled and ready for transfer to the jobsite.

To ensure seamless service, our dispatch team works closely with the contractor to coordinate delivery schedules. For local projects, we go a step further by providing installation support upon arrival at the jobsite. With a fleet of 10 delivery trucks, including six equipped with cranes, we offer added convenience and cost savings to contractors. These cranes lift and set products into place, saving on installation time, labor, and equipment, and lowering risk. Additionally, our dedicated field service representatives are available to assist with installation, ensuring proper product placement and system connection.

With our comprehensive delivery and service capabilities, the Houston plant is committed to providing exceptional support to our customers throughout every stage of their projects.