What is FOG?

In 2010, the Environmental Protection Agency (EPA) estimated that 23,000 to 75,000 SSOs and a similar amount of basement backups occur annually. These spills equate to approximately 10 billion gallons of raw sewage per year being discharged. Fat, Oil and Grease commonly referred to as FOG contributes to approximately 47% of these spills, according to the EPA.

It includes by-products of cooking. Typical sources include: food scraps, meat fats, plant oils,cooking oil, butter, margarine, sauces, gravy, mayonnaise, salad dressing, baked goods, cheese, dairy products and deep-fried foods. Other sources include body oils, lotions, oily residue from laundering and lipid-soluble hydrocarbons. The chemical composition of FOG includes free fatty acids, triglycerides, ester waxes, phospholipids, sterols and phytosterols. It enters the sanitary sewer system from restaurants, residences and industrial activities through direct introduction into a drain, washing these products down the sink with hot water or inadequate grease control.

How does FOG cause a SSO?

FOG settles on the interior of pipe and other surfaces as it flows through the sewer system. Over time, the FOG mixes with other constituents such as calcium, sodium and phosphorus, found in the sewage, forming a hard soap like compound. The results of this build up includes: severe reduction in pipe flow capacity, slow drains, sewage backups, contact with disease carrying bacteria, corrosion of sewer lines and costly repairs.

A study completed by North Carolina State University for the EPA found that FOG deposits preferentially accumulated on root surfaces and in pipe sag regions as well as areas where pipes had increased surface roughness. The study noted that FOG formation occurred with a wide range of pH although the higher pH produced visually significant more solids.

How to reduce or prevent FOG from entering the sewer system?

Activities that citizens can do to reduce FOG from entering the sewer system include:

- Do not pour fat, oil or grease down drains or garbage disposals.

- Do not use hot water to rinse grease off cookware, utensils, dishes or surfaces.

- Use paper towel to clean up oil spills and throw in to trash.

- Washing oil dish clothes in a washing machine still introduces oil (FOG) into the sewer system.

For restaurants, commercial food services and industrial activities with FOG production there is only one method, that is to control FOG buildup from the source. This method includes recycling cooking oil, reduce the amount of food waste entering sewer system through washing and the installation of a grease interceptor, which separates FOG from the waste stream.

Solution

ParkUSA® offers a wide variety of infrastructure products to address FOG, for interception and system repair.

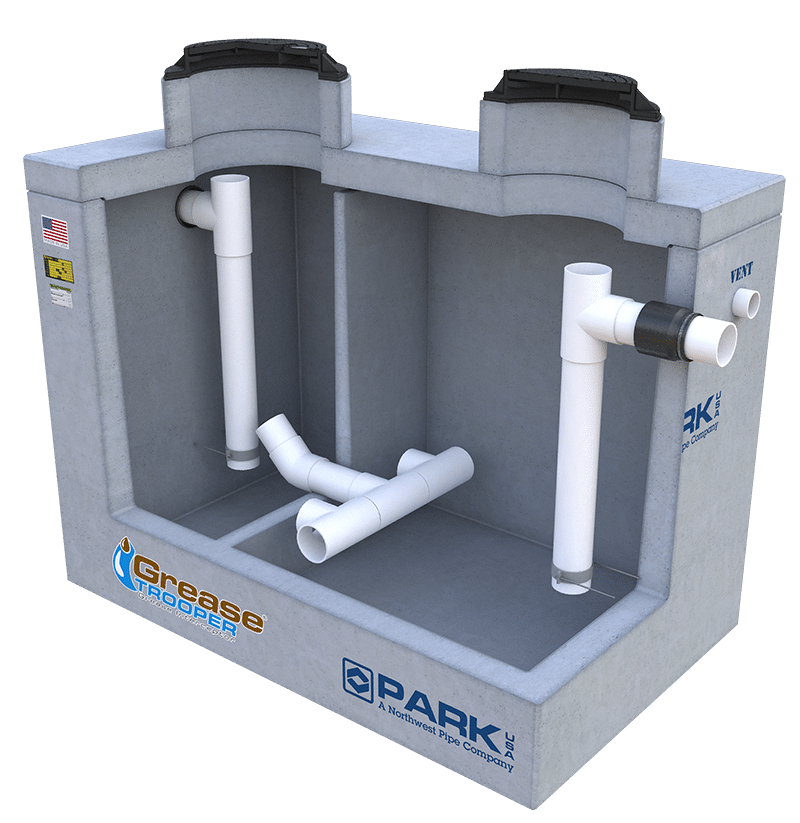

ParkUSA® GreaseTrooper® is a family of gravity interceptor devices designed to reduce the amount of FOG in wastewater. Grease interceptors work on the buoyancy principle. Fats and oils are 10 to 15 percent less dense than water and do not mix with water. Thus, fats and oils float on top of water. When wastewater enters a grease interceptor, the velocity is reduced enough that wastewater is given time to cool and separate into 3 layers. The fats and oils rise to the top inside the interceptor and are trapped using a system of baffles. Solids settle at the bottom, and the separated clear water escapes under an outlet baffle. Grease interceptors can also have strainers for collecting solid debris, which reduce the quantity of solids that settle at the bottom of the interceptor. Over time, solid and grease buildup will accumulate in the grease interceptor. A routine cleaning schedule will ensure maximum performance of each interceptor.

The ParkUSA® OilTrooper® Model SOCMP is a sand-oil interceptor that consist of a multicompartment basin and patented enhanced separation technology for sediment and oil separation. Typical applications include vehicle maintenance and washrack facilities, fueling depots, industrial areas, parking lots, and storm water runoff. The OilTrooper sand-oil interceptor is used to meet wastewater pretreatment code requirements.

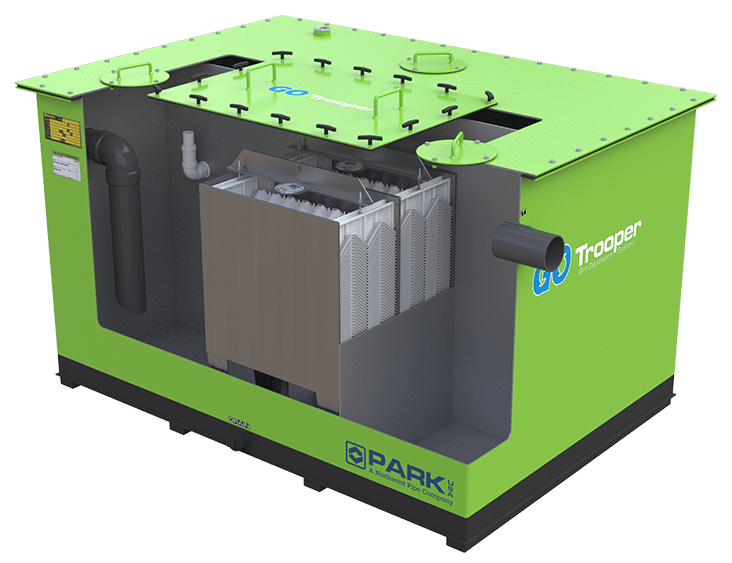

ParkUSA® GOTrooper® is a Grit-Oil Interceptor that intercepts cosmetic wash water. The unit can be designed to function as a gravity flow or pumped-driven system. The wastewater flows into an inlet chamber, passes through a baffle and oleophilic coalescing plate pack to separate oil and solids. The discharging effluent is the clearer water underneath the floating oils.

ParkUSA® Manhole OPS (overflow protection system) is a system that includes a lined manway with a pressure rated ring and cover that is suitable for preventing overflows due to system surcharging and infiltration from flood waters. ParkUSA® offers customized systems to address any unique and challenging sewer system SSO situation.

Our Responsibility

ParkUSA® believes in water technology development to combine efficiency and environmentally friendly products. ParkUSA’s goal is to offer its customers sustainable green solutions that meet today’s needs, as well as anticipated changes in regulations.

Contact us for more information and design assistance.